OZ-Racing

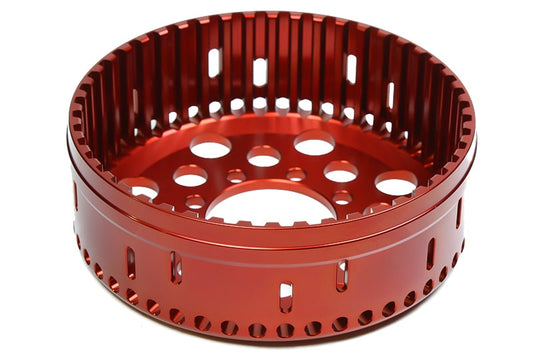

DUCATI Panigale V4/V4S/V4R Forged Mag Wheel Made in Italy OZ-Racing Genuine CATTIVA StreetFighterV4 Mag Forged DU102012C-60B

DUCATI Panigale V4/V4S/V4R Forged Mag Wheel Made in Italy OZ-Racing Genuine CATTIVA StreetFighterV4 Mag Forged DU102012C-60B

Couldn't load pickup availability

SKU:DU102012C-60B-gb

Items with the title "In stock in Italy" will arrive by express delivery within 7 to 10 business days after placing your order.

Once the stock is sold out, reservations will be made for the next arrival and will be shipped as soon as they arrive, with a delivery time of approximately 2 to 4 weeks. Inventory may change at any time.

(Delivery dates may vary depending on the manufacturer, customs clearance, etc.; orders may be concentrated during the race season, so delivery dates may be delayed)

OZ Racing forged magnesium wheels CATTIVA front and rear set

F3.50-17

R6.00-17

DU102012C-60B

DUCATI Panigale V4/V4S/V4R/1299/1199

DUCATI StreetFighter V4/V4S

OZ -Racing genuine forged magnesium wheel CATTIVA Made in Italy (MADE IN ITALY)

``Mono Retech'' is a large-diameter one-piece monocoque hub structure that uses cutting-edge technology to hollow out the inside of the hub using a special cutting process. The front wheel is basically a one-piece structure that is not equipped with a disc flange except for some car models, and we took pains to cut it to reduce the weight in grams, including the design of the disc rotor mounting part. The spoke shape also provides excellent running feel and higher rigidity that cannot be achieved with straight spokes found on wheels that rotate at high speeds. CATTIVA is finished with a glossy black powder coating after a techno-shot peening process in which special spherical ceramic micro balls are hit against the wheels.

Techno shot peening treatment

The "techno shot peening" process used in CATTIVA, in which special spherical ceramic micro balls are hit against the wheel using special equipment, changes the chemical arrangement of molecules on the metal surface and increases the density, resulting in a smooth finish for the wheel. Technology that can increase surface hardness by 15%. This is a technology cultivated on the four-wheeled F-1, and is something that has never been seen before on two-wheeled wheels, and is truly a technology unique to OZ Racing.

Similar to the aluminum forged wheel "PIEGA", the product is made by compression molding the material using a press, and is characterized by high strength and tenacity. Instead of simply pressing from the top and bottom, O.Z wheels are manufactured using a true forging method that applies pressure of over 20,000 tons from multiple directions to crush the metal and refine the internal crystals. We use advanced molds that can compression mold to the ideal shape, making full use of the world's top level forging press.

design

Magnesium uses a 6-spoke design. The ideal shape simulated by 3DCG and the advanced cutting technology that makes it a reality. The low weight, which is a characteristic of magnesium wheels, has been further improved by complex cutting using O.Z technology without sacrificing strength.

Surface finish

In addition to the forging process and heat treatment, ``CATTIVA'' is also treated with ``shot peening'', a technology adopted to further improve strength. Ceramic shot peening treatment (ceramic shot) is applied to the wheel surface, improving surface hardness by 20-25%. The final surface finish, which is the key to the look, is carefully painted black.

Component part

All parts other than the wheel body are made by cutting "7075 material" called extra super duralumin material. Pursuing a design that focuses on lightweight and functional beauty.

spoke structure

In order to achieve both rigidity and weight reduction, the spoke structure adopts a "U-shaped cross-sectional shape" with a large gouge on the rear surface in the direction of rotation. In addition, we have thoroughly examined the design in terms of functionality and appearance, such as side pocket processing and lightweight hole design.

C3102DU35X+C6012DU60X_NLV

C3102DU35X+C6012DU60X_NOV

C3102DU35X+C6012DU60X_OLV

OZ-6S CATTIVA

``Mono Retech'' is a large-diameter one-piece monocoque hub structure that uses cutting-edge technology to hollow out the inside of the hub using a special cutting process. The front wheel is basically a one-piece structure that does not have a disc flange except for some car models, and we took great care in machining to reduce the weight in grams, including the design of the disc rotor mounting part. The spoke shape also provides excellent running feel and higher rigidity that cannot be achieved with straight spokes found on wheels that rotate at high speeds. CATTIVA is finished with a glossy black powder coating after a techno-shot peening process in which special spherical ceramic micro balls are hit against the wheels.

Techno shot peening treatment

The "techno shot peening" process used in CATTIVA, in which special spherical ceramic micro balls are hit against the wheel using special equipment, changes the chemical arrangement of molecules on the metal surface and increases the density, resulting in a smooth finish for the wheel. Technology that can increase surface hardness by 15%. This is a technology cultivated on the four-wheeled F-1, and is something that has never been seen before on two-wheeled wheels, and is truly a technology unique to OZ Racing.

Manufacturing method

Manufacturing method

Similar to the aluminum forged wheel "PIEGA", the product is made by compression molding the material using a press, and is characterized by high strength and tenacity. Instead of simply pressing from the top and bottom, O.Z wheels use a true forging method that applies pressure of over 20,000 tons from multiple directions to crush the metal and refine the internal crystals. We use advanced molds that can compression mold to the ideal shape, making full use of the world's top level forging press.

design

design

Magnesium uses a 6-spoke design. The ideal shape simulated by 3DCG and the advanced cutting technology that makes it a reality. The low weight, which is a characteristic of magnesium wheels, has been further improved by complex cutting using O.Z technology without sacrificing strength.

Surface finish

Surface finish

In addition to the forging process and heat treatment, ``CATTIVA'' is also treated with ``shot peening'', a technology adopted to further improve strength. Ceramic shot peening treatment (ceramic shot) is applied to the wheel surface, improving surface hardness by 20-25%. The final surface finish, which is the key to the look, is carefully painted black.

Component part

Component part

All parts other than the wheel body are made by cutting 7075 material, which is called extra-super duralumin material. Pursuing a design that focuses on lightweight and functional beauty. (The finish is unified with black hard alumite.)

spoke structure

spoke structure

In order to achieve both rigidity and weight reduction, the spoke structure adopts a "U-shaped cross-sectional shape" with a large gouge on the rear surface in the direction of rotation. In addition, we have thoroughly examined the design in terms of functionality and appearance, such as side pocket processing and lightweight hole design.

damper system

Adopts a damper system with various ingenuity for functionality and durability. The rubber is made of high-quality material and at the same time has ample capacity, and the damper bearing is also a large-capacity type with excellent durability.

share

In stock at our shop. Same day shipping is available for orders placed by 4pm on weekdays.

-

In stock DUCATI Genuine Parts Regulator 3 Phase GR-2 54040111C 54040191A Ducati 98 and later Garuda

Vendor:DUCATI4.9 / 5.0

(8) 8 total reviews

Regular price $98.00Regular priceUnit price / per$151.00Sale price $98.00Sale -

In stock PROGRIP Superbike 717 Grip Racing Pro Grip Superbike DUCATI Genuine Part Number 96280611AA 96280611AB Panigale V4

Vendor:ProGrip4.5 / 5.0

(4) 4 total reviews

Regular price $19.00Regular priceUnit price / per$34.00Sale price $19.00Sale -

In stock DUCATI genuine Panigale V4/V4R oil filter 2 genuine O-rings + genuine drain washer set 88650761A + 85250541A PanigaleV4

Vendor:DUCATI5.0 / 5.0

(1) 1 total reviews

Regular price $7.00Regular priceUnit price / per$9.00Sale price $7.00Sale -

In stock DUCATI genuine Panigale 1299/1199/959/899 for oil filter 2 genuine O-rings + genuine drain washer set 88650561A + 85250541A Panigale

Vendor:DUCATI5.0 / 5.0

(5) 5 total reviews

Regular price $9.00Regular priceUnit price / per$10.00Sale price $9.00Sale -

In stock DUCATI Genuine Parts Oil Filter 44440039A Ducati Genuine 44440038A 44440037A

Vendor:DUCATI4.9 / 5.0

(7) 7 total reviews

Regular price $17.00Regular priceUnit price / per$19.00Sale price $17.00Sale -

In stock 44440312B DUCATI Genuine Parts Panigale V4/1299/1199/899/959/V2 Panigale Oil Filter Ducati 44440291C

Vendor:DUCATI5.0 / 5.0

(2) 2 total reviews

Regular price $23.00Regular priceUnit price / per$26.00Sale price $23.00Sale -

DUCATI CORSE Genuine Emblem Logo Decal Ducati Corsa 43815811A Superleggera V4 Multistrada V4 Pikes Peak

Vendor:DUCATI5.0 / 5.0

(1) 1 total reviews

Regular price $19.00Regular priceUnit price / per$19.00Sale price $19.00 -

In stock Brembo genuine clutch fluid tank cover small brembo S15 reservoir tank cover 60x40mm red logo 1 piece 99.8637.66

Vendor:brembo5.0 / 5.0

(2) 2 total reviews

Regular price $11.00Regular priceUnit price / per$11.00Sale price $11.00 -

In stock Termignoni Genuine Heat Resistant Sticker Italy Termignoni Genuine 1 Piece Heat Resistant Decal Heat Resistant Sticker DUCATI

Vendor:Termignoni5.0 / 5.0

(2) 2 total reviews

Regular price From $8.00Regular priceUnit price / per$9.00Sale price From $8.00Sale -

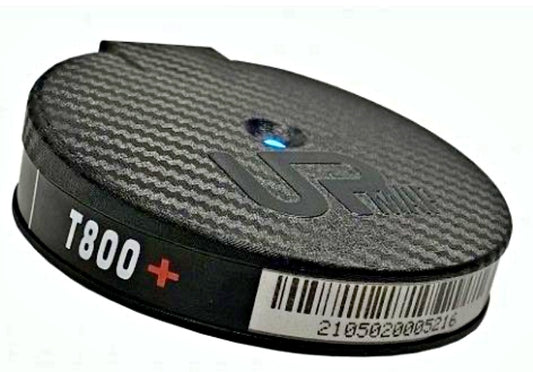

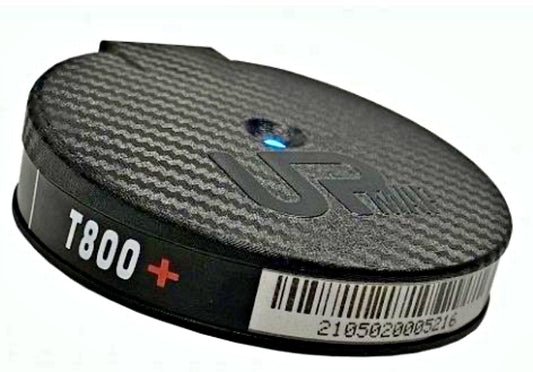

Termignoni UpMap T800 Plus Panigale V4 V2 DUCATI Panigale V4 Street Fighter V4 Multistrada V4 UpMap UP-Map+ECU connection cable Euro4 Euro5 full power

Vendor:DUCATISM5.0 / 5.0

(1) 1 total reviews

Regular price $375.00Regular priceUnit price / per$402.00Sale price $375.00Sale -

In stock K&N KN-159 DUCATI Panigale oil filter Panigale V4/1299/1199/899/959/ SF V4 44440312B equivalent

Vendor:K&N4.4 / 5.0

(5) 5 total reviews

Regular price $16.00Regular priceUnit price / per$19.00Sale price $16.00Sale -

Asutsuku DUCATI genuine neutral switch 53910072A + with genuine copper gasket ring DUCATI genuine product 900SS M900 916 748

Vendor:DUCATI4.6 / 5.0

(5) 5 total reviews

Regular price $36.00Regular priceUnit price / per$37.00Sale price $36.00Sale -

In stock New Brembo genuine product new logo brake fluid tank cover large brembo S50 reservoir tank cover 70x70mm red logo 1 piece 99.8637.56

Vendor:brembo5.0 / 5.0

(2) 2 total reviews

Regular price $12.00Regular priceUnit price / per$12.00Sale price $12.00 -

In stock DUCATI 900SS M900 888 916 996 748 999 749 1098 1198 848 Genuine Starter Motor Brush 067050815 set Assembly

Vendor:DUCATI5.0 / 5.0

(5) 5 total reviews

Regular price $38.00Regular priceUnit price / per$40.00Sale price $38.00Sale -

In stock DUCATI genuine oil pressure switch countermeasure product + with genuine aluminum gasket ring DUCATI genuine genuine product 69921511A

Vendor:DUCATI5.0 / 5.0

(1) 1 total reviews

Regular price $32.00Regular priceUnit price / per$33.00Sale price $32.00Sale -

In stock DUCATI genuine dry clutch push rod 11721122A Ducati 900SS/SS1000DS 916/996/998

Vendor:DUCATI5.0 / 5.0

(5) 5 total reviews

Regular price $44.00Regular priceUnit price / per$45.00Sale price $44.00Sale -

In stock NGK MAR9A-J DUCATI genuine spark plug 67040451A Panigale 1299/1199/899/959 Diavel Multistrada 1200 Monster 1200 Ducati Panigale Ducati 6869

Vendor:NGK4.0 / 5.0

(1) 1 total reviews

Regular price $23.00Regular priceUnit price / per$39.00Sale price $23.00Sale -

In stock PM160S Sprint Filter DUCATI Panigale V4/V4S/V4R Air Cleaner Panigale V4 Sprint Filter P08 Genuine Replacement Type

Vendor:Sprint FilterRegular price $92.00Regular priceUnit price / per$97.00Sale price $92.00Sale -

Asutsuku MALOSSI Malossi 750F1 Manifold DUCATI "F1-Rear" Intake Manifold 1 piece

Vendor:Dellorto5.0 / 5.0

(2) 2 total reviews

Regular price $25.00Regular priceUnit price / per$28.00Sale price $25.00Sale -

Dynamic lighting LED turn signal set 96680961BA DUCATI PanigaleV4 turn indicator set Panigale V4 DP genuine

Vendor:DUCATI Performance5.0 / 5.0

(4) 4 total reviews

Regular price $98.00Regular priceUnit price / per$108.00Sale price $98.00Sale -

In stock DUCATI genuine anti-rotation insert 71320043A DUCATI 900SS/SS1000DS 916 /996 /998

Vendor:DUCATIRegular price $6.00Regular priceUnit price / per$12.00Sale price $6.00Sale -

In stock DUCATI genuine relay 54140101A Panigale 1299/1199/Monster1100/1200 /1198/1098 54140101A

Vendor:DUCATIRegular price $9.00Regular priceUnit price / per$10.00Sale price $9.00Sale -

In stock 1 Year Domestic Warranty CTEK MXS5.0 Charger 2023 Edition Next Generation 12V Battery Charger 40-206 Seatech Japanese Instruction Manual Old MUS4.3

Vendor:CTEK5.0 / 5.0

(4) 4 total reviews

Regular price $107.00Regular priceUnit price / per$144.00Sale price $107.00Sale -

In stock DUCATI genuine radiator cap DUCATI genuine genuine product 89340061A Monster S4, S4R, S4RS ST4, ST4S 749,R,S/999,R,S

Vendor:DUCATI5.0 / 5.0

(2) 2 total reviews

Regular price $17.00Regular priceUnit price / per$21.00Sale price $17.00Sale -

Asutsuku May sale finally appeared brembo Corsa Corta radial clutch master 16RCS 16x16-18 110.C740.50 Brembo Corsa Corta DUCATI 110C74050

Vendor:DUCATIRegular price $40.00Regular priceUnit price / per$41.00Sale price $40.00Sale

Items in stock, delivered tomorrow

Inventory is updated in real time and is constantly changing. Hurry up.

-

Brembo DUCATI 996R/996/748 320mm genuine disc 1 piece Brembo rare 49240261A

Regular price $282.00Regular priceUnit price / per$365.00Sale price $282.00Sale -

In stock 1 Year Domestic Warranty CTEK MXS5.0 Charger 2023 Edition Next Generation 12V Battery Charger 40-206 Seatech Japanese Instruction Manual Old MUS4.3

5.0 / 5.0

(4) 4 total reviews

Regular price $107.00Regular priceUnit price / per$144.00Sale price $107.00Sale -

In stock 303 Aerospace Protectant, Approx. 473ml, Aerospace Protectant, Domestic Regular Import

5.0 / 5.0

(1) 1 total reviews

Regular price $19.00Regular priceUnit price / per$19.00Sale price $19.00 -

In stock 44440312B DUCATI Genuine Parts Panigale V4/1299/1199/899/959/V2 Panigale Oil Filter Ducati 44440291C

5.0 / 5.0

(2) 2 total reviews

Regular price $23.00Regular priceUnit price / per$26.00Sale price $23.00Sale -

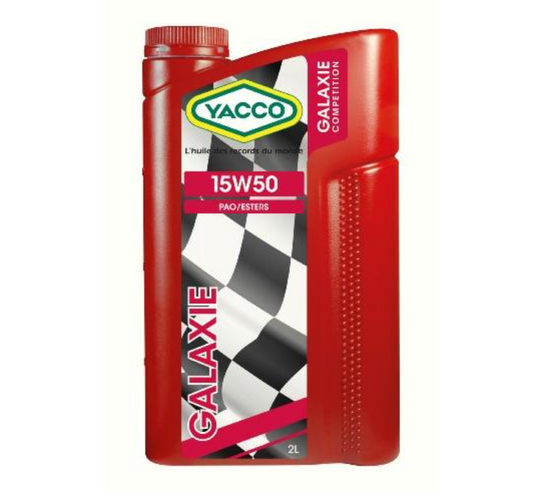

In stock 15W-50 YACCO GALAXIE 2L Bottle 1 Domestic Regular Import Yakko Galaxy Engine Oil

5.0 / 5.0

(2) 2 total reviews

Regular price $54.00Regular priceUnit price / per$60.00Sale price $54.00Sale -

In stock brembo STYLEMA radial monoblock 4P brake caliper 100mm left and right set with pad 220.D020.10

Regular price $742.00Regular priceUnit price / per$830.00Sale price $742.00Sale -

Asuku ABUS GRANIT CITY CHAIN X-PLUS 1060 1100mm Length 110cm New Model Strongest Chain Lock Abs/Abas

Regular price $169.00Regular priceUnit price / per$187.00Sale price $169.00Sale -

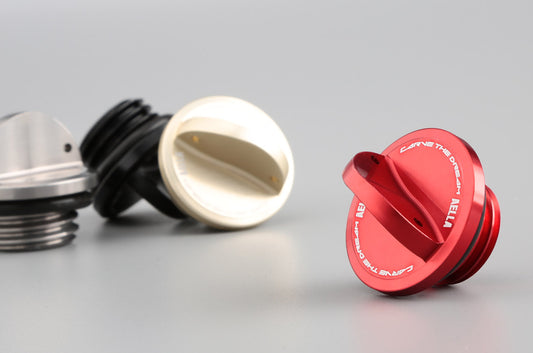

Asutsuku AELLA AE-52007 DUCATI Panigale machined drain plug V4/1299/1199/959/899 Panigale

Regular price $28.00Regular priceUnit price / per$28.00Sale price $28.00 -

Asutsuku AELLA AE-52007 DUCATI Panigale machined drain plug V4/1299/1199/959/899 Panigale

Regular price $28.00Regular priceUnit price / per$28.00Sale price $28.00 -

In stock AELLA AE-52007 DUCATI Panigale machined drain plug V4/1299/1199/959/899 Panigale

5.0 / 5.0

(1) 1 total reviews

Regular price $29.00Regular priceUnit price / per$30.00Sale price $29.00Sale -

Asutsuku AELLA AE-71007 black oil filler cap hexagonal hole type DUCATI Panigale V4/1299/1199/959/899/Monster 1200/Scrambler

Regular price $29.00Regular priceUnit price / per$30.00Sale price $29.00Sale -

Asutsuku AELLA AE-71007 black oil filler cap hexagonal hole type DUCATI Panigale V4/1299/1199/959/899/Monster 1200/Scrambler

Regular price $29.00Regular priceUnit price / per$30.00Sale price $29.00Sold out -

In stock AELLA AE-71007 black oil filler cap hexagonal hole type DUCATI Panigale V4/1299/1199/959/899/Monster 1200/Scrambler

4.5 / 5.0

(2) 2 total reviews

Regular price $29.00Regular priceUnit price / per$30.00Sale price $29.00Sale -

Asutsuku Ohmmu Tesla Model X for 12V Lithium Battery 12V Lithium Battery for TESLA Model X T1240X

Regular price $22.00Regular priceUnit price / per$29.00Sale price $22.00Sale -

Asutsuku Brembo rear caliper 2pod 34φ red b mark titanium color 84mm with pad 20B85278 Brembo genuine product red logo 20.B852.73

Regular price $13.00Regular priceUnit price / per$14.00Sale price $13.00Sale -

Asutsuku Brembo rear caliper 2pod 34φ red b mark titanium color 84mm with pad 20B85278 Brembo genuine product red logo 20.B852.73

5.0 / 5.0

(1) 1 total reviews

Regular price $101.00Regular priceUnit price / per$105.00Sale price $101.00Sale -

Asutsuku Brembo genuine oil tank cover large brembo S50 reservoir tank cover 80x50mm black/red logo 1 piece 99.8637.56

Regular price $16.00Regular priceUnit price / per$16.00Sale price $16.00 -

Asutsuku Brembo genuine oil tank cover large brembo S50 reservoir tank cover 80x50mm black/red logo 1 piece 99.8637.56

Regular price $7.00Regular priceUnit price / per$7.00Sale price $7.00 -

In stock brembo caliper aluminum piston left and right set br660 with pad titanium color red logo 20.5165.79 20.5165.89 Brembo genuine

Regular price $151.00Regular priceUnit price / per$173.00Sale price $151.00Sale -

Asutsuku Brembo genuine oil tank cover large brembo S50 reservoir tank cover 80x50mm black/red logo 1 piece 99.8637.56

Regular price $3.00Regular priceUnit price / per$3.00Sale price $3.00 -

In stock brembo radial brake master Corsa Corta 19 RCS φ19x18-20 110.C740.10 Brembo Corsa Corta DUCATI V4

4.8 / 5.0

(5) 5 total reviews

Regular price $364.00Regular priceUnit price / per$402.00Sale price $364.00Sale -

Brembo rear caliper 2pod 34φ red b mark titanium color 84mm with pad 20B85278 Brembo genuine product red logo 20.B852.73

Regular price $124.00Regular priceUnit price / per$144.00Sale price $124.00Sale -

Asutsuku Brembo genuine oil tank cover large brembo S50 reservoir tank cover 80x50mm black/red logo 1 piece 99.8637.56

Regular price $16.00Regular priceUnit price / per$16.00Sale price $16.00 -

Asutsuku Brembo genuine oil tank cover large brembo S50 reservoir tank cover 80x50mm black/red logo 1 piece 99.8637.56

Regular price $7.00Regular priceUnit price / per$7.00Sale price $7.00Sold out -

Asutsuku brembo genuine counter mat 99.8637.84 size 60 x 40 cm weight about 600g

Regular price $32.00Regular priceUnit price / per$34.00Sale price $32.00Sale

Items in stock, delivered tomorrow

Inventory is updated in real time and is constantly changing. Hurry up.

-

In stock KA739 OHLINS Ohlins rear suspension Kawasaki Z900RS/Z900/Performance/Cafe 2017-2021 Kawasaki

5.0 / 5.0

(2) 2 total reviews

Regular price $931.00Regular priceUnit price / per$1,051.00Sale price $931.00Sale -

In stock DUCATI Scrambler 800 2021-2022 Racing Titanium Manifold for E-D8E2 Akrapovic s-d8sO6-Isssbl

5.0 / 5.0

(1) 1 total reviews

Regular price $835.00Regular priceUnit price / per$865.00Sale price $835.00Sale -

In stock brembo STYLEMA radial monoblock 4P brake caliper 100mm left and right set with pad 220.D020.10

Regular price $742.00Regular priceUnit price / per$830.00Sale price $742.00Sale -

Asutsuku DUCATI Panigale V4R (-2022) V4SP V4SP2 Dry Clutch Disc Kit STM SBK Evo Ducati Panigale V4R DUCATI Genuine Product 19020552A

Regular price $471.00Regular priceUnit price / per$513.00Sale price $471.00Sale -

Asutsuku DUCATI PanigaleV4 StreetFighterV4 Rear Short Tail Guard Ducati Panigale V4 V2 DP Genuine 97381161AA 97381162CA

5.0 / 5.0

(2) 2 total reviews

Regular price $471.00Regular priceUnit price / per$485.00Sale price $471.00Sale -

Asutsuku Termignoni UpMap T800 Plus Panigale V4 V4S V4SP V2 DUCATI Panigale V4 Street Fighter V4 Multistrada V4 Upmap UP-Map+ECU connection cable Euro4 Euro5

5.0 / 5.0

(2) 2 total reviews

Regular price $375.00Regular priceUnit price / per$402.00Sale price $375.00Sale -

Termignoni UpMap T800 Plus Panigale V4 V2 DUCATI Panigale V4 Street Fighter V4 Multistrada V4 UpMap UP-Map+ECU connection cable Euro4 Euro5 full power

5.0 / 5.0

(1) 1 total reviews

Regular price $375.00Regular priceUnit price / per$402.00Sale price $375.00Sale -

In stock brembo radial brake master Corsa Corta 19 RCS φ19x18-20 110.C740.10 Brembo Corsa Corta DUCATI V4

4.8 / 5.0

(5) 5 total reviews

Regular price $364.00Regular priceUnit price / per$402.00Sale price $364.00Sale -

May Sale TWM TDPR01 Racing Tank Cap Quick Type DUCATI 1198/1098/ 998/996/748 Monster900/1000 SS900/SS1000DS

5.0 / 5.0

(2) 2 total reviews

Regular price $332.00Regular priceUnit price / per -

Asutsuku GR-3 regulator GARUDA general purpose 3-phase lithium battery for 282-013 DUCATI

Regular price $307.00Regular priceUnit price / per$395.00Sale price $307.00Sale -

Suflex S1815 Wet clutch disc DUCATI 750F1 (type 1), 400F3, 400SS, M400

Regular price $301.00Regular priceUnit price / per$305.00Sale price $301.00Sale -

In stock Surfflex S1816 DUCATI dry clutch disc SURFLEX lightweight aluminum friction plate Ducati 998/996/916/748-999/749 900SS M900 M1000

5.0 / 5.0

(4) 4 total reviews

Regular price $295.00Regular priceUnit price / per$305.00Sale price $295.00Sale -

Brembo DUCATI 996R/996/748 320mm genuine disc 1 piece Brembo rare 49240261A

Regular price $282.00Regular priceUnit price / per$365.00Sale price $282.00Sale -

In stock DUCATI multimedia system Ducati Multistrad V4/STREETFIGHTER V4/Panigale V4 DUCATI performance genuine SCRAMBLER 96680711A 96680712B

Regular price $282.00Regular priceUnit price / per$303.00Sale price $282.00Sale -

DUCATI Z48T Dry Clutch Disc kit STM DUCATI ADU-0030 STM Genuine

Regular price $276.00Regular priceUnit price / per$303.00Sale price $276.00Sale -

DUCATI Dry Clutch Outer Basket STM DUCATI ADU-0010 Italy Genuine STM

Regular price $244.00Regular priceUnit price / per$263.00Sale price $244.00Sale -

DUCATI Multistrada V4 rider heated low seat MULTISTRADA V4 V4S Ducati 96880921AA DUCATI performance genuine product

Regular price $238.00Regular priceUnit price / per$251.00Sale price $238.00Sale -

Assuku DUCATI Multistrada 950 genuine BRACKET FOOTREST REAR RIGHT 82413131AB made in italy

Regular price $226.00Regular priceUnit price / per$251.00Sale price $226.00Sale -

Finally in stock! SURFLEX S1816 DUCATI dry clutch disc lightweight aluminum friction plate Ducati 998/996/916/748-999/749 900SS M900 M1000 Ducati

Regular price $208.00Regular priceUnit price / per$214.00Sale price $208.00Sale -

In stock Malossi Malossi DUCATI bevel intake manifold front and rear set Dellorto PHM40 Dellorto

Regular price $187.00Regular priceUnit price / per$195.00Sale price $187.00Sale -

In Stock Ducati Corse Large Headlight Fairing 1299 Panigale 959 Smoke Gray 97180251A Ducati Genuine Product

Regular price $182.00Regular priceUnit price / per$234.00Sale price $182.00Sale -

Asuku ABUS GRANIT CITY CHAIN X-PLUS 1060 1100mm Length 110cm New Model Strongest Chain Lock Abs/Abas

Regular price $169.00Regular priceUnit price / per$187.00Sale price $169.00Sale -

5/12 Stock in Italy May Sale DUCATI Panigale V4/V4S/V4R Adjustable Step Kit 96280481B Panigale Footpeg Kit Ducati Performance Genuine Genuine

Regular price $158.00Regular priceUnit price / per$166.00Sale price $158.00Sale -

In stock CTEK MUS4.3 TEST&CHARGE Sea Tech 12V Battery Charger Test & Charge Battery Tester 1 Year Warranty

5.0 / 5.0

(1) 1 total reviews

Regular price $156.00Regular priceUnit price / per$182.00Sale price $156.00Sale -

In stock brembo caliper aluminum piston left and right set br660 with pad titanium color red logo 20.5165.79 20.5165.89 Brembo genuine

Regular price $151.00Regular priceUnit price / per$173.00Sale price $151.00Sale